Guide to Interior LED Retrofits

LED lighting technology is the best commercially available choice for lighting. The great thing is that LEDs can be used for both interior and exterior applications. We previously wrote a guide for specifying an exterior LED retrofit, and we will follow it up with this guide to interior retrofits. Interior LED retrofits cover anything inside a building, such as offices, manufacturing facilities, warehouses, retail stores, and even your house. This guide will focus on commercial and industrial buildings as they have greater energy savings potential due to larger areas to illuminate and generally higher footcandle requirements than other applications.

Many interior applications use fluorescent tubes for office and retail settings and metal halide high bay fixtures for manufacturing and warehouse settings. It is important to know which lighting technology you are replacing in order to choose the appropriate LED – once you know that, you can continue with the rest of the retrofit. The key elements to an interior LED retrofit are below.

- Wattage

- Lumens

- Life Hours

- Fixture Type

- Color Temperature

Wattage

LEDs are the most efficient light fixture available for retrofits and are always going to use less wattage than any comparable fixture by light output. This energy reduction will vary depending on the existing lighting technology – fluorescent fixtures are usually replaced at a ratio of 2.5 to 1 LED wattage, and metal halide fixtures are usually replaced at a ratio of 3 to 1 LED wattage.

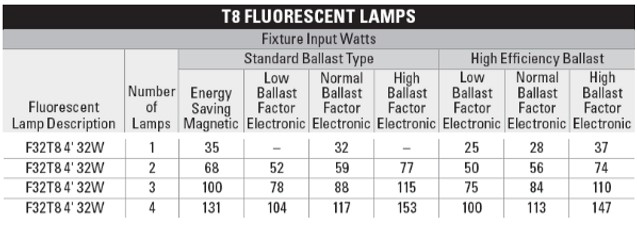

Both metal halide and fluorescent fixtures use a ballast to operate, and it increases the total wattage consumed by a lamp. There are many tools that exist to help find the total wattage of any quantity or type of fluorescent or metal halide office fixture. A quick online search should bring up tools similar to the table below.

Table of common T8 fluorescent lamp ballast wattage

A common office overhead light fixture is a troffer style with four F32T8 4ft 32W fluorescent tubes. These are the 2ft by 4ft rectangular ceiling lights seen in most commercial offices. To figure out what wattage LED we need, the following calculation occurs.

4 tubes x 32W per tube = 128W, but we have to account for the ballasts. So we go back to that table and look for F32T8 4ft 32W in the first column. Then we find the appropriate number of lamps (in this case, four) and identify the standard energy saving magnetic ballast (131W). Thus, the total wattage of this fluorescent light fixture is 131W.

We take 131W and apply the 2.5 to 1 ratio. 131W/2.5 = 52.4W, which we will round to 53W. This means that a 53W LED fixture will be an equivalent replacement for the four fluorescent tubes. LED fixture wattages will vary depending on the manufacturer and you may not be able to get the exact wattage equivalent. In that case, choosing a fixture wattage within a 10W range above or below the target wattage will generally be sufficient. Colite Technologies recommends using 50W 2ft x 4ft LED panel light fixtures to replace 4-tube F32T8 4ft 32W fluorescent fixtures.

Now you know what wattage of fixture you should be looking for. If you are unsure of the type or wattage of your existing lights, it is usually labeled on the fixture itself. If it is not labeled, contact a lighting expert and they can help you find the information or suggest an approximate fixture. However, since the wattage equivalents are not always exact, it is good to look at other qualities of the light fixtures as well.

Lumens

Lumens are the measurement of a fixture’s light output and determine the amount of illumination a light fixture can provide. When evaluating an LED replacement fixture, the lumen amount should be about the same as the old fixture to ensure you are getting a similar light output. If you want a brighter light, choose a fixture with higher lumens. This information can be found on the label located on the lamp with the wattage information.

You will often see a lumen per watt specified for an LED light fixture. This serves as a reference to the operational efficiency of the fixture. Many LEDs can provide 120 to 130 lumens/watt compared to an average of 75 lumens/watt for both fluorescent and metal halide fixtures. As a result, it explains the ability to drastically reduce energy use while maintaining a similar light output when switching to LED.

In practice, the lumen output will not tell you how the light will be distributed in an area. For this measurement, we use footcandles (fc). One footcandle roughly equates to the light output of a single candle in a one square foot area, or one lumen per square foot. Different applications have different footcandle requirements – an office space generally requires a minimum of 30 fc, but a grocery store parking lot requires a minimum of 5 fc. Depending on the type of activity that occurs in the space, the lighting requirements may vary by company, location, and/or application.

The lighting layout will determine light distribution throughout the area and is summarized in a photometric report, which most lighting providers and manufacturers can give you. It can be helpful in identifying dark spots, wiring needs, fixture additions or removals, and simply comparing your old lighting to your new LED lighting.

Life Hours

Operational life hours are a simple, but critical, component of LED retrofits. LED light fixtures last for 50,000 hours as an industry standard. In a sample office application where we assume a five-day workweek, the lights are on 10 hours a day for 260 days per year. This equates to an astonishing 19 years of operation before the LEDs burn out. As a comparison, fluorescent fixtures are rated for 20,000 hours of operation and metal halide fixtures are rated for 10,000 hours of operation; using the same example scenario, the fluorescents would fail in less than 8 years and metal halide in less than 4 years.

LEDs save a significant amount of money in maintenance costs – especially if it requires equipment rental to reach the fixtures or hiring an electrician to replace them – and it keeps a uniform look in the facility. It is common to see offices or warehouses that have some lights not working, as it is tedious to replace each light as it goes out and it disrupts work each time. Some facilities may opt to wait until more lights fail before replacing them to decrease the number of work interruptions or equipment rentals. Thus, the result is spotty lighting and eventual darkening of the office or warehouse.

Fixture Type

After you have determined the technical aspects of the retrofit fixture, you can move on to the visual aspects. There are a variety of styles of light fixtures to fit desired aesthetics, space, and levels of illumination. In commercial and industrial applications, the priority considerations are often the amount of space that needs to be illuminated and the level at which it is illuminated. Warehouses and manufacturing facilities with high ceilings will have high bay fixtures that spread light over a wide area and office or retail spaces will have recessed can lights, troffers, and panel light to provide more directed light.

The most common interior bulb type is the fluorescent tube. They are cheap, easy to find, and easy to replace. Most light fixtures use multiple fluorescent tubes, like the common troffer fixture that houses four parallel F32T38 tubes. When replacing these lights, you can replace each tube with an LED tube, or count the four tubes as one unit and replace it with an LED panel. In a big project, it saves a considerable amount of time and money to replace four tubes as a unit since you only have to rewire it once instead of four times.

Metal Halide lights almost exclusively come in the form of bulbs. As an example, a warehouse might have several bell-shaped fixtures that hold a light bulb. These can be replaced with a corn cob LED fixture and reuse the bell-shaped shade or replace it with a flat disk-shaped UFO LED fixture. Since you are removing and rewiring the entire fixture in both situations, either fixture type will be a good option – it simply depends on the desired look. Both the corn cob and the UFO are designed for wide area illumination from high ceilings.

“Plug and Play” versus Ballast Bypass

There are interior and exterior retrofit options known as “plug and play” that allow you to simply remove an old light bulb and replace it with a new LED bulb in the same housing. While this method works in the short term and may be slightly cheaper, it continues to use the ballast which increases the overall wattage consumption of your LED and increases the chances of fixture failure. Not only does this impact your energy savings from the retrofit, it also leads to more headaches down the line with replacements.

LED technology is not intended to use ballasts and therefore Colite Technologies strongly recommends bypassing the ballast entirely and rewiring the whole fixture. When looking for an LED fixture, choose the type that requires rewiring – they are often labeled “ballast bypass” or it will be specified in the installation instructions. It is important to remember that rewiring electric wires should always be done by an electrician and is very dangerous to do without the proper knowledge and training. Your lighting retrofit partner will identify and install the appropriate fixture for you, but it never hurts to review the retrofit plan.

Color Temperature

Like exterior retrofits, the color temperature of the light fixtures will affect the visual color of the interior. Most offices and warehouses select a neutral, white color for their lighting because it accurately reflects colors, is easy to see, and does not put excessive strain on the eyes. The color temperature, also referred to as correlated color temperature (CCT), is measured in Kelvin (K) and based on the spectrum of color that a piece of steel shines when brought to specific temperatures, measured in Kelvin. White light fixtures come in 3000K (warm white), 4000K (neutral white), and 5000K (daylight white). The appropriate color temperature will depend on the application – a lower color temperature results in a yellow-orange light and a higher color temperature results in a bluer light. Therefore, a coffee shop may choose a 3000K color temperature to give a warm, welcoming feel to their interior, but a doctor’s office may choose a 5000K color temperature to bring a bright, clean atmosphere to the space. Most commercial offices utilize 3000K to 4000K color temperatures because it offers a warm to neutral feel for employees and visitors without being harsh.

In short, there are a lot of criteria to consider when choosing a replacement LED. The best fixture is determined by the setting, lighting needs, cost, and visual appeal of the light fixture itself. Interior lighting retrofits are very similar to exterior retrofits – they can substantially improve your energy efficiency, cut energy and maintenance costs, and modernize the facility just like exterior retrofits do. Additionally, many utilities offer financial rebates for LED retrofit projects that help decrease total project costs.

If you are looking for an LED retrofit partner, reach out to one of our team members today. Colite Technologies will curate a turnkey, custom retrofit plan for your facility from start to finish. We handle everything from the existing lighting audit, to the replacement fixture identification and sourcing, project cost analysis, rebate application process, and the installation of new LED light fixtures. Whether interior, exterior, or both, we can help guide you to better, more efficient lighting for the entire facility.